plug flow reactor solved problems pdf

Number of tubes 16 26. The plug flow reactor is the second-most primary ideal reactor and is similar to the continuous stirred tank bioreactor.

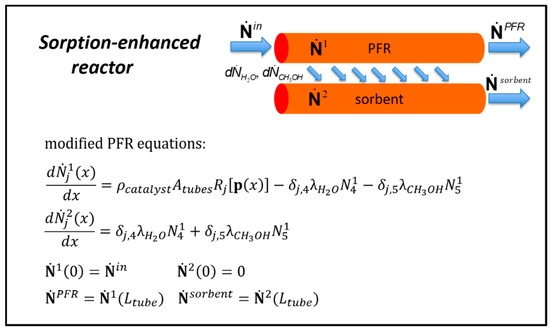

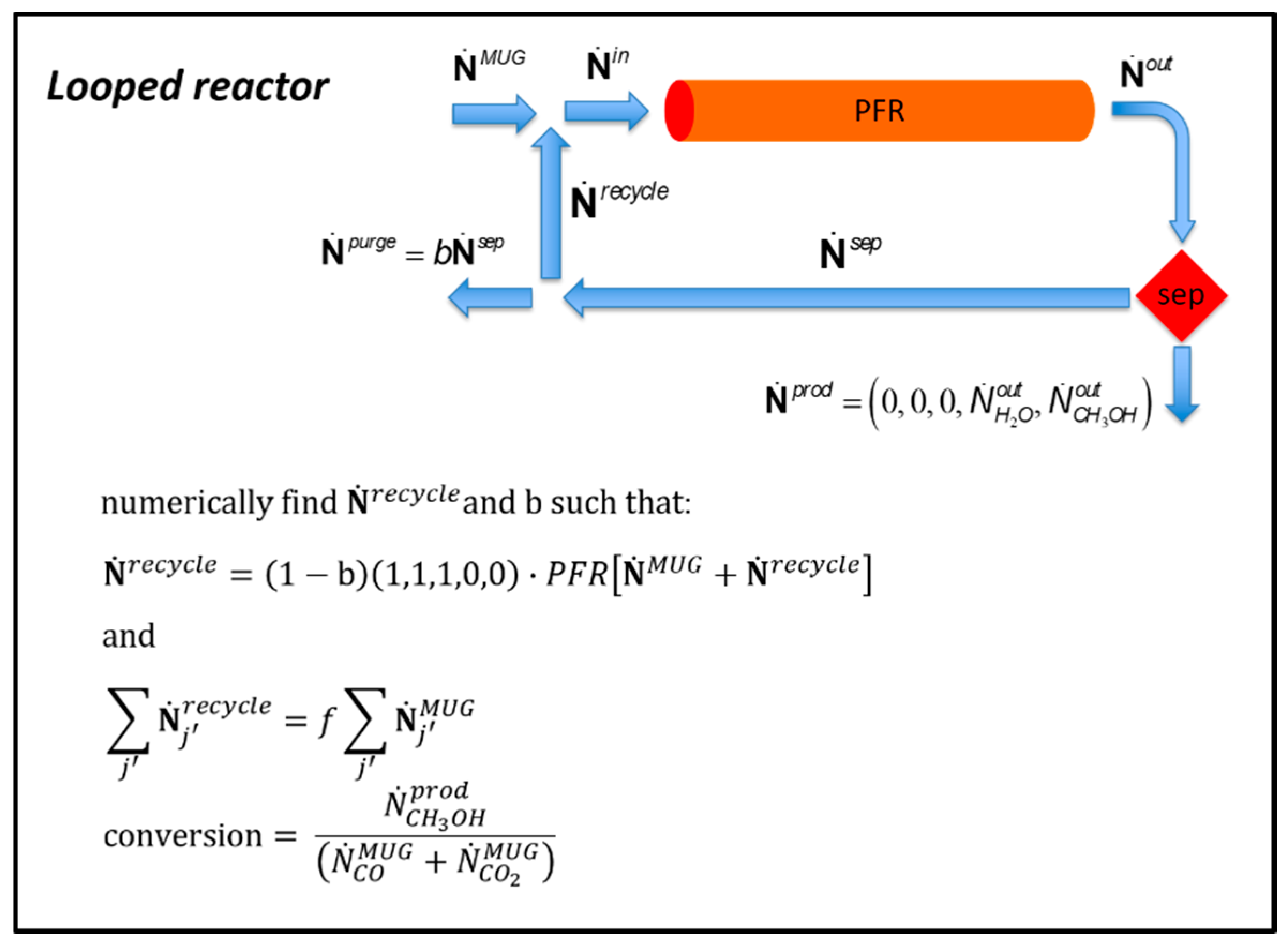

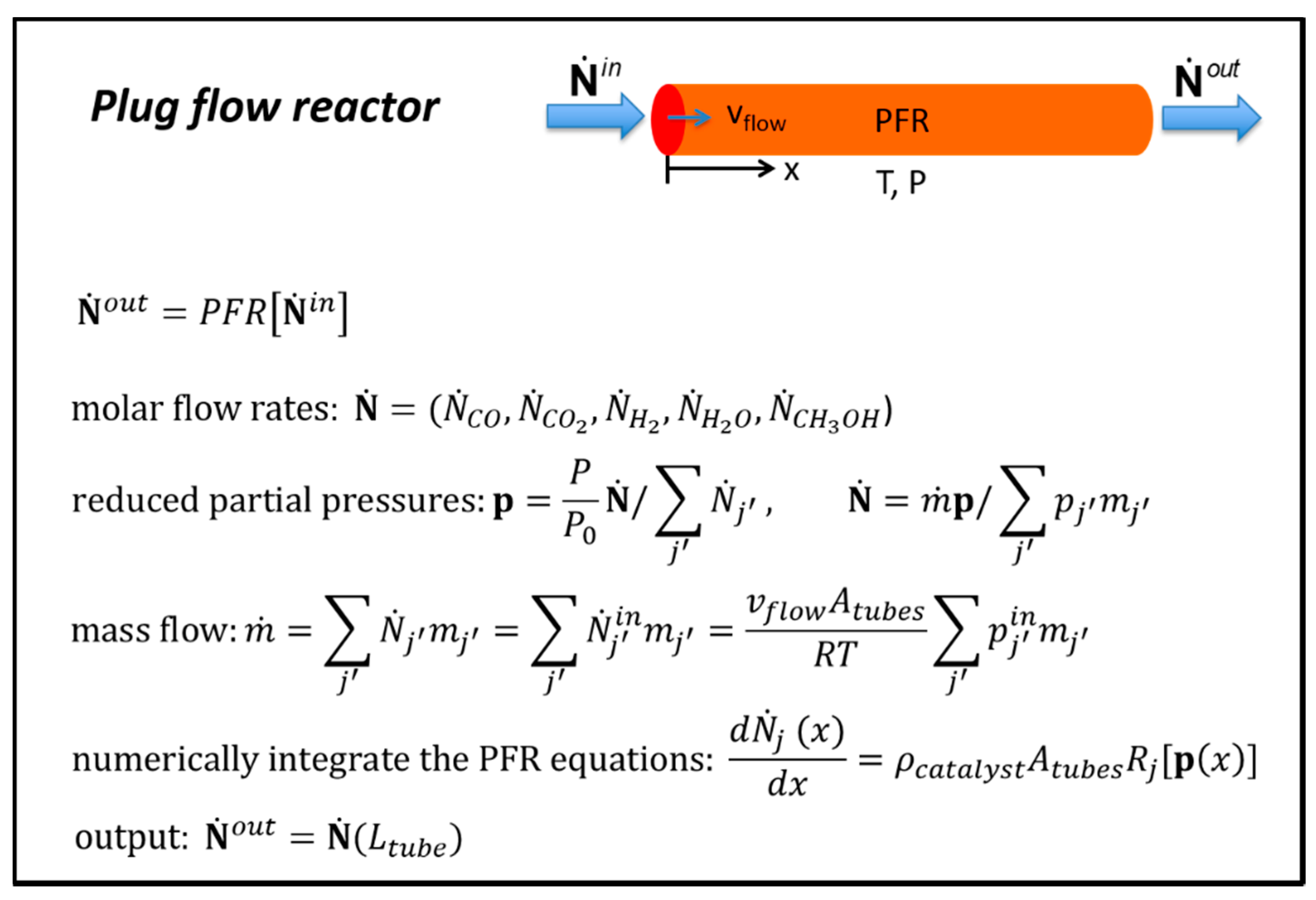

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

A τ 0974 min.

. David Reckhow CEE 370 L9 5. The temperature in the reactor is prescribed a. Both PFR and BR.

David Reckhow CEE 370 L9 4 Brominated DBPs. Download Calculation Of Plug Flow Reactor Design. Reactor PBR is intensively studied and used widely Eigenberger 1997.

Tz T o isothermal reactor. How choice of reactor affects selectivity vs. Clearly state all assumptions used in your derivation.

3If there is zero conversion at the entry to the PFR and 60 at the exit. The volume of a PFR can be represented as the shaded area in the Levenspiel Plot shown below. B n Rf 2958 kmolh 27.

In such reactors the reaction rate expression must be. General Algorithm for Solving Isothermal Reactor Problems. Chapter 3 discusses the mechanics of actually running the program and pre-processors and then Chapter 4 discusses the keyword input used in specifying the problem to be solved.

A catalytic process is used for the synthesis of ammonia. Access article on Wiley Online Library HTML view. Here polymerization and conversion reactions are performed in noncatalytic mode.

A short summary of this paper. Plug flow reactors volume. These reactors provide enough residence time for the reaction to take place with satisfactory conversion.

Stoichiometry relate concentration to volume and number of moles for batch reactors or to volumetric flow rate and molar flow rate for flow reactor. To allow uniform flow through the pipe the pipe was set on a traditional laboratory stand placed at both ends Fig. 1-11 Strategy to Solve This Problem The solution to this problem requires an analysis of multiple gas-phase reactions in a differential plug-flow tubular reactor.

There are some situations where a transient. Given -r A as a function of conversion one can size any type of reactor. Batch Reactor BR D.

LAB REPORT ON PLUG FLOW REACTOR L5 4 f40. A T T0 387 K. ξAf 0600 30.

A ξeq 0867 T eq 784 K. V 165 m3 33. V 271 m 3 25.

Rate Laws Write down rate law in terms of limiting reactant. Equations reactor sizing for constant volume and variable volume processes. General Mole Balance Equation GMBE 2.

Figure 4 is a picture of the plug flow injection setup. CHEMICAL REACTORS 2011-2012 Course SOLUTION TO PROBLEMS OF PLUG FLOW REACTOR 23-35 23. Depends on the reaction order E.

4 and at the middle of the reactor. This method is used to determine the rate constants for. WHG Lecture 6 correction.

V 3317 L 24. Basic types of problems 1. Two different solution strategies are.

Thus it allows for con-. DC d r C Ideal batch. Combining reactors with separations.

In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR. The two feed streams to the reactor mix to form a single fee d. The elementary liquid-phase irreversible reaction.

V 103 m3 29. The reaction occurs along the flow path. The integral to calculate the PFR volume can be evaluated using a method such as Simpsons One-Third Rule pg 925.

B T 0 433 K 32. Your answer by calculating the reactor volume in liters and the outlet molar flow rate of triethanolamine that correspond to your design. Retainment of homogeneous catalysts The fi rst membrane reactor concept shown in Figure 11 exploits the membrane to retain in the reactor soluble homogeneous catalysts.

V 203 L 28. 2 To determine the reaction rate constant. WHG 9 Reactor size comparisons for PFR and CSTR.

2Assuming these assumptions are all met calculate the plug flow reactors volume to achieve a 60 conversion given a feed rate of 15mols 1 to the reactor. Chapter 5 discusses post-processing options. You will learn how to formulate models for transient PFRs though.

Transient plug flow reactor problems that require the use of equations 271 and 272 will not be solved in this course but their solution will be described without going into the numerical details. Completely Mixed Flow Reactor CMFR C. You previously purchased this article on READCUBE_PURCHASE_DATE.

37 Full PDFs related to this paper. Integrate 8 or 13 and find extent along the reactor. Debasree Ghosh Lecture notes on Polymer Reaction Engineering Module II.

Up to 10 cash back Abstract A method is described to solve the inverse problem of chemical kinetics estimation of the rate constants for elementary steps of chemical reactions from the data of nonstationary experiments in an open isothermal plug-flow reactor without using optimization algorithms. 29 Of course. 9 or 14 find the heat additionremoval requirement along the reactor and the overall heat duty for the reactor.

Compare ideal batch and ideal PFR mass balances. This document was uploaded by user and they confirmed that they have the permission to share it. B V 150 L 31.

KDW 8 The plug flow reactor. The polymerization of ethylene and the conversion of naphtha to ethylene are examples. LAB REPORT ON PLUG FLOW REACTOR L5 3 f30 OBJECTIVES The objectives of the experiment are- 1 To carry out a saponification reaction between sodium hydroxide NaOH and ethyl acetate Et AC.

Click on an option below to access. Thoughts on Problem Solving. Is to be carried out in a flow reactor.

38 Full Text and PDF Download. DC dt r C Position in a PFR is equivalent to time in a batch reactor x C. The reactor itself may consist of an empty.

3 To determine the effect of residence time on the conversion. Reactors in series and in parallel. Integrate 8 or 13 find ξz.

One approach to solve this material balance is to use the fractional conversion of one of the materials. Two reactors are available an 800 dm 3 PFR that can only be operated at 300 K and a 200 dm 3 CSTR that can be operated at 350 K. The fraction conversion is defined as.

It serves as a reference in several sections of this book. Design of Ideal Reactors Plug-flow reactor PFR A plug-flow reactor PFR may be used for both liquid-phase and gas-phase reactions and for both laboratory-scale investigations of kinetics and large-scale production. Schematic of Plug Flow Reactor.

Learn more Check out. If you are author or own the copyright of this book please report to us by using this DMCA report form. Plug Flow Reactor PFR B.

What is the conversion. The outlet was connected to flexible tubing which emptied into the sink. In Chapter 2 governing equations for the plug flow reactor are first summarized for reference.

An optimal control problem solved for SO2 oxidation Eivind Johannessen u0001 Signe Kjelstrup Department of Chemistry Norwegian University of Science and Technology.

Pdf Plug Flow Reactor Model Wikipedia The Free Encyclopedia Praveenkumar Dtv Academia Edu

Matlab In Chemical Engineering At Cmu

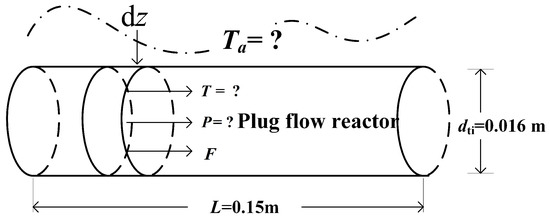

Pdf Modeling The Non Isothermal Plug Flow Reactor Performance Evaluation

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

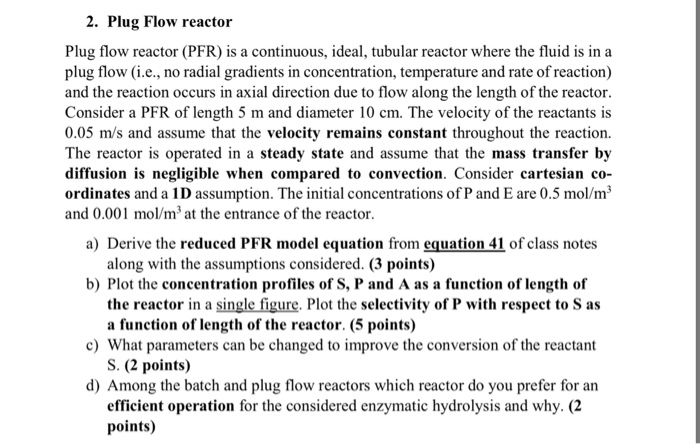

2 Plug Flow Reactor Plug Flow Reactor Pfr Is A Chegg Com

Plug Flow Reactor An Overview Sciencedirect Topics

Chemical Reactors Problems Of Plug Flow Reactor 23 35 4c2h2

Plug Flow Reactor Model Wikiwand

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

Entropy Free Full Text Entropy Generation Rate Minimization For Methanol Synthesis Via A Co2 Hydrogenation Reactor Html

Solved 4 You Are Designing A Reactor That Uses Chlorine In A Pfr Or Cstr 1 Answer Transtutors

Pfr And Cstr In Series A Youtube

Solved Problem 4 An Aqueous Reactant Stream At The Chegg Com